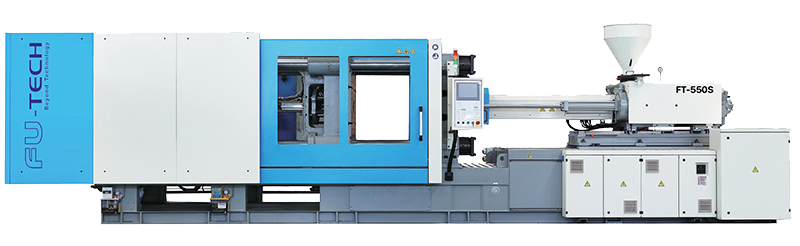

FT SERIES

Injection Moulding Machines

Introduced in 2018, the FT Series is the general purpose injection moulding machine that provides a budget solution for your needs. The FT Series starts from 110 Ton upto 1100 Ton.

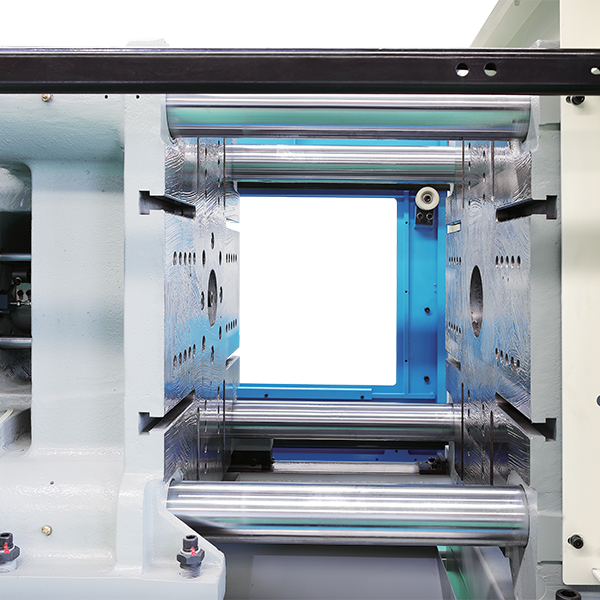

Clamping Unit

- Larger space between tie-bars, suitable for larger and multi-cavity molds.

- Longer and wider guide length, higher precision, improved product quality and mold working life.

- Graphite-Copper bushes in Tie-Bar, slider movable platen ensures fast and precise mold close and open.

- Better designed mechanical structure and toggle system for faster cycle time and improved production efficiency.

- European type Ejector System.

- Spacios structure design for upgrades and retrofits.

- Rigid platen and mechanical systems ensures longer machine life.

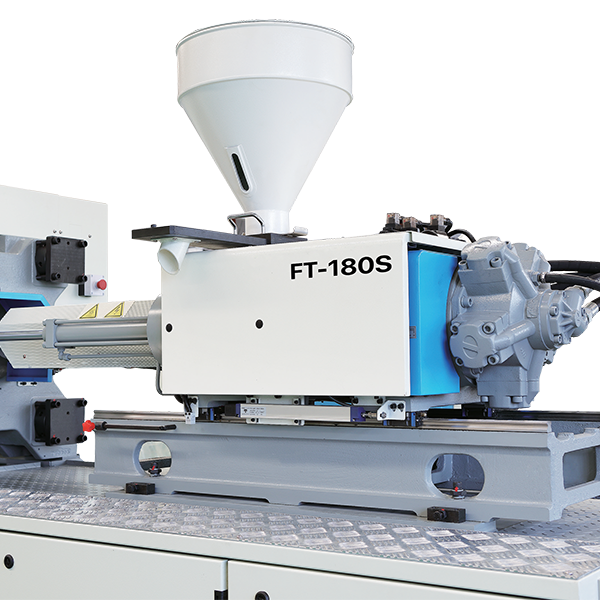

Injection Unit

- Injection unit with dual precise linear guide rails, ensuring the best precision and fast speed

- Dual carriage cylinders improve a better injection precision

- No welding, Adaptor design ensures easier maintenace and repairs

- Upturning designed nozzle cover make production and maintenance easier

- Imported high quality SKD61 material ring, cone and plunger; lots of screw design can meet different plastic materials and special processing injection molding needs

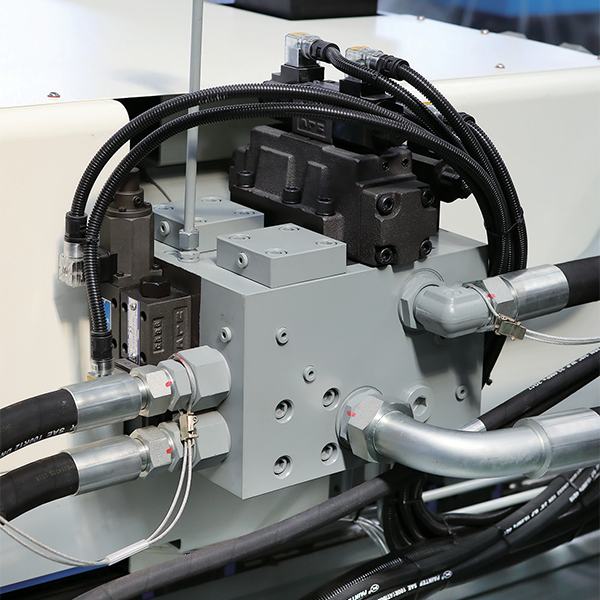

Hydraulic Unit

- Standard precise and energy saving Servo Motor System, energy saving capacity can reach to 20%-80% than traditional injection machine.

- Hydraulic parts from reputed brands ensure machine’s reliability and fast response time.

- Visible and dischargeable oil tank, easy for hydraulic maintenance.

- Modular adaptor valve blocks, hydraulic circuit and functions make upgrade and maintenance easy.

- Self-sealed magnetic suction filter, makes machine’s maintenance more convenient.

- Logical distribution of pump oil suction port, oil drain and hydraulic pipe fittings makes maintenance easier.

- German DIN standard hydraulic pipe fitting with seal, G screw thread style plug to avoid oil seepage.

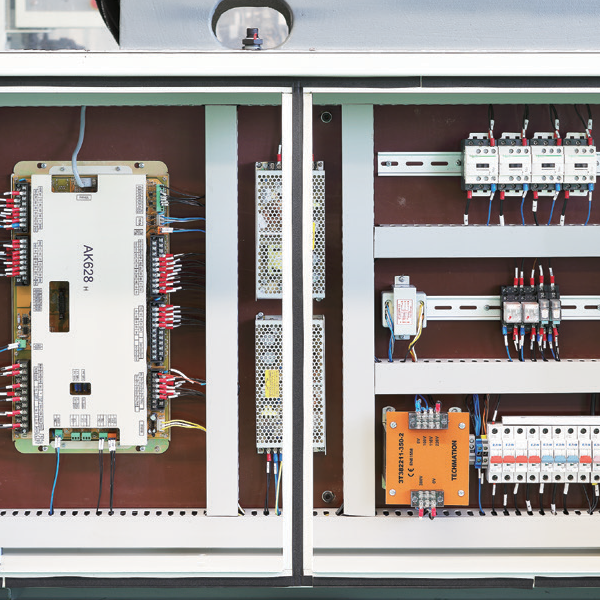

Electrical Unit

- Electric parts from reputed brands

- High quality large colour screen controller with multiple languages

- Standard equipped LED three-colour tower light with alarm, ensures clear visibility of machine status on shop floor

- Modernized network management function available

- Water-proof rubber seal used on electric cabinet ensure high safety

- Machine program according to CE safety standard.