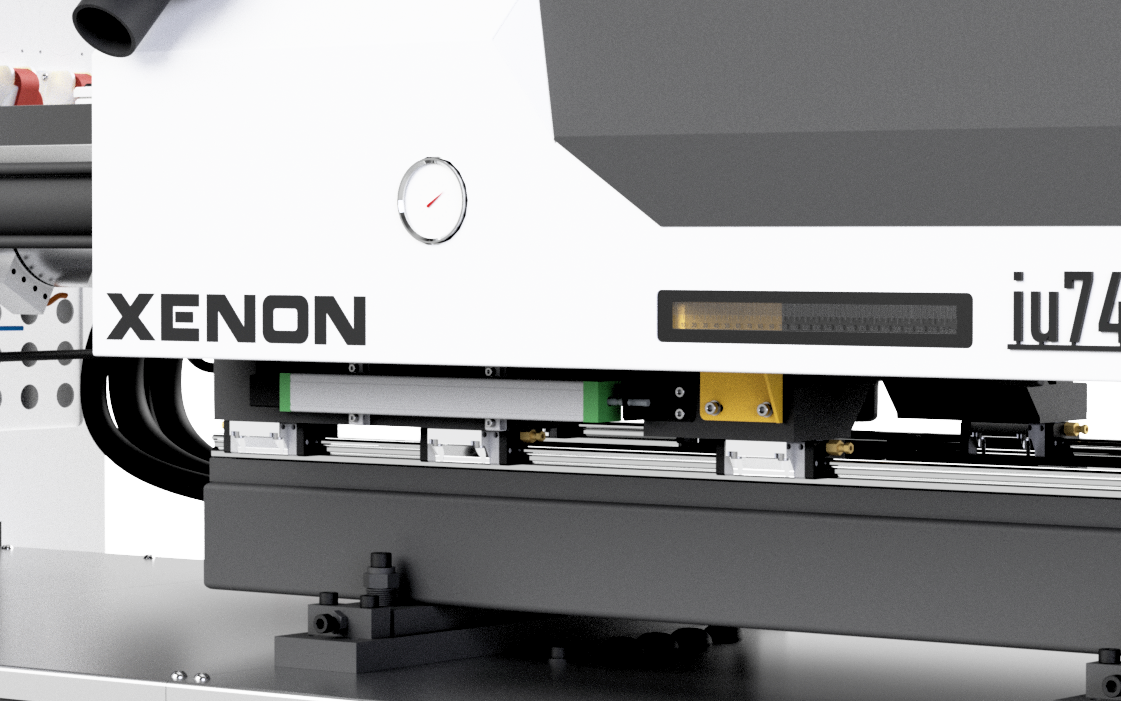

XENON SERIES

Injection Moulding Machines

The XENON Series is our latest high performance offering ranging from 110 Ton to 550 Ton. Equiped with high speed servo system, these machines are ideal for High Efficiency and suiteable for applications like automotive, Medical, Toys etc.

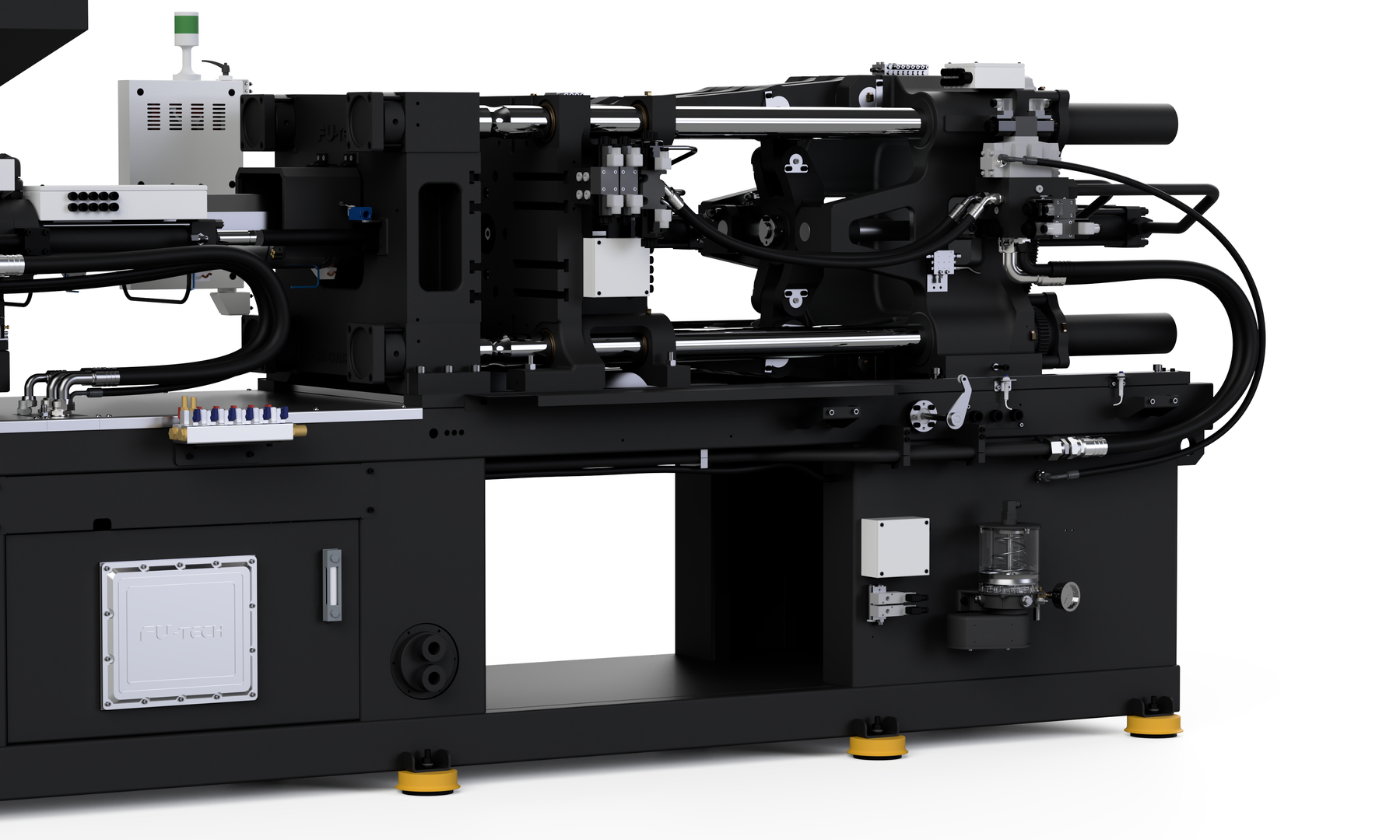

Clamping Unit

- Smart Toggle design offers smooth clamp velocity profile

- Optimised platen design to ensure durability and mechanical rigidity

- Advanced Auto-Die Height adjustment feature

- High Graded Bearing Steel alloy Toggle Bushes and Pins

- Optimised Grooving Design for toggle bushings

- Progressive type closed loop lubrication system

- High speed platen axis movement without jerks and spikes

- Easy to Clean Heat Exchanger Design

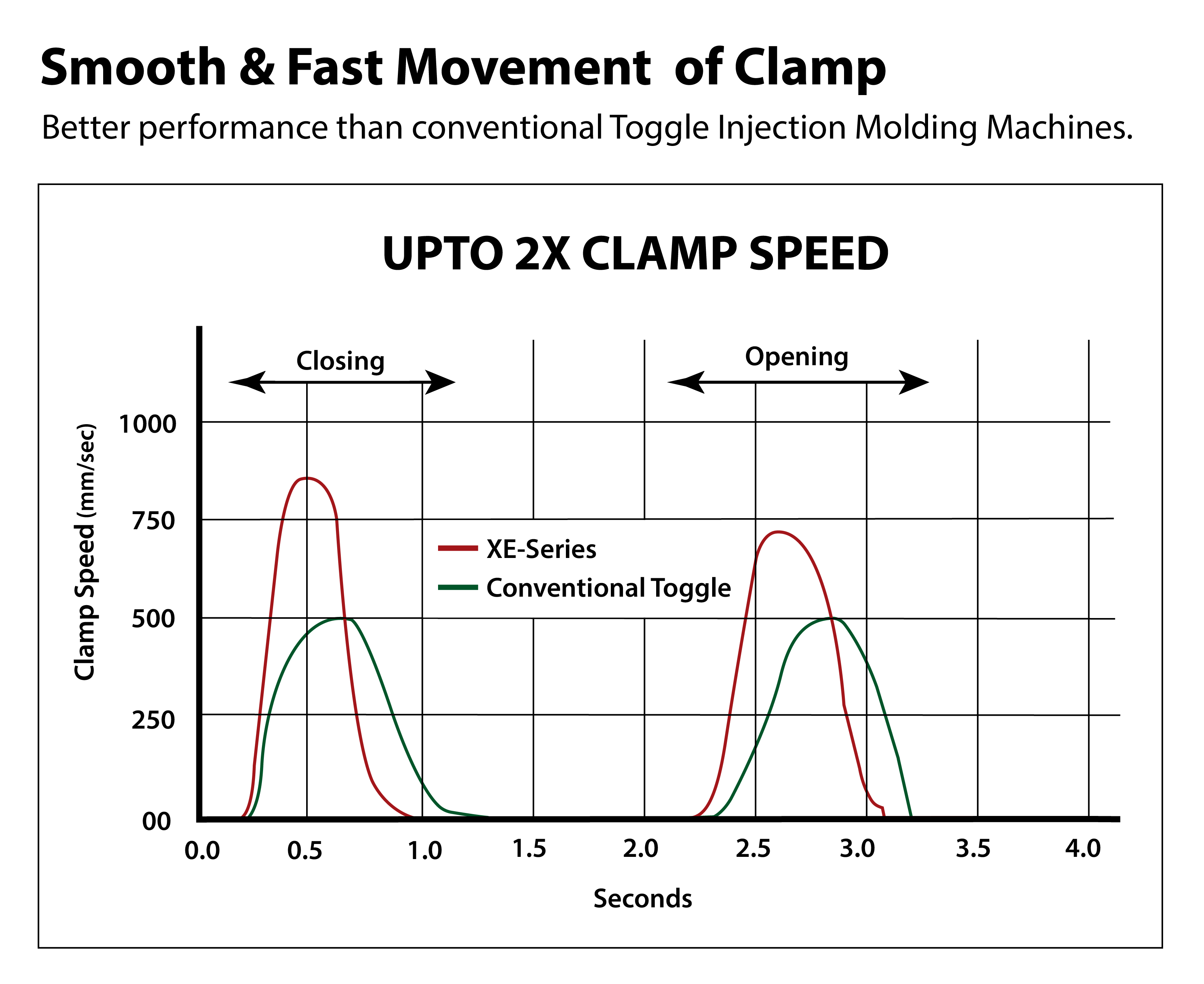

Smart Clamp Control

The Smart clamp control in The XENON is a very advance feature which offer a very smooth high speed movement with unmatched accuracy and precision.

Optimised Toggle Mechanism

The Enhanced toggle geometery offers faster Locking buildup and a smooth decompression of toggle clamp.This enables the machine to offer lowest Dry Cycle time.

Smooth and Fast Clamp Movement

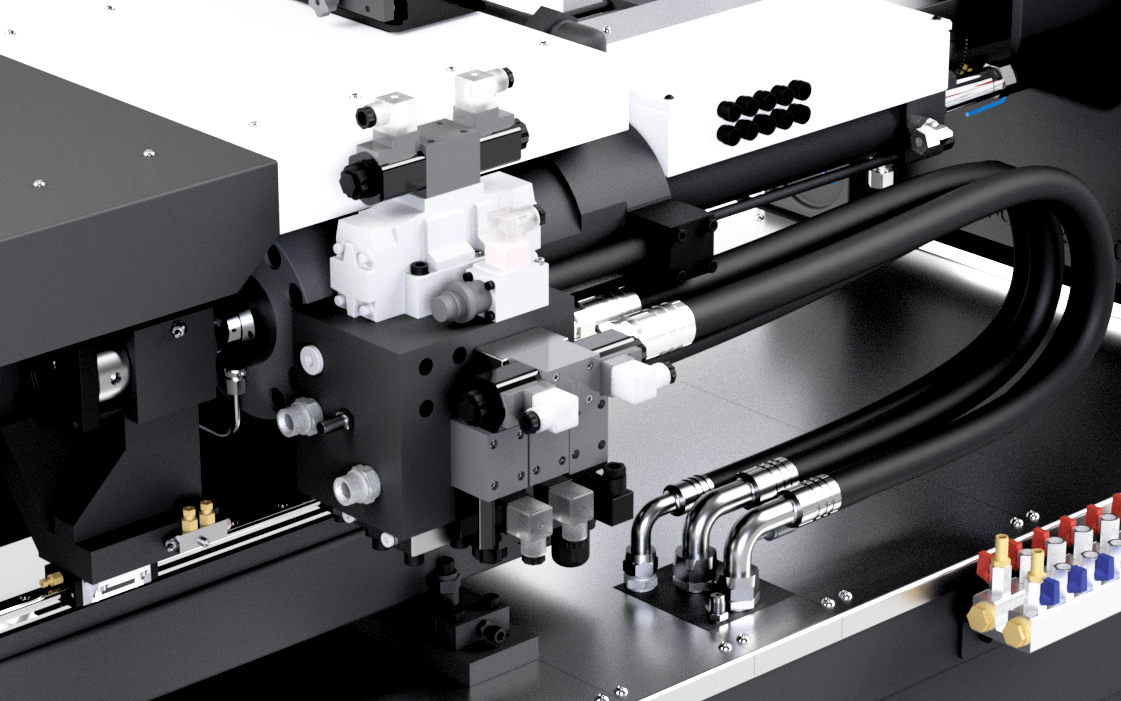

The smoothest hydraulic circuit is designed in the XENON, this hydraulic design offers very smooth clamp platen movement and braking just before mold touch position.

Advanced Strength Analysis

The XENON is designed on latest mechanical platforms to ensure the complete mechanical rigidity is achieved. The force distribution on the Clamping platen is optimised for longer life of machine..

Uniform Load on Mould

The smart design of Moving platen ensures the forces from toggle is evenly distributed on the mould surface, hence increasing the mould life.

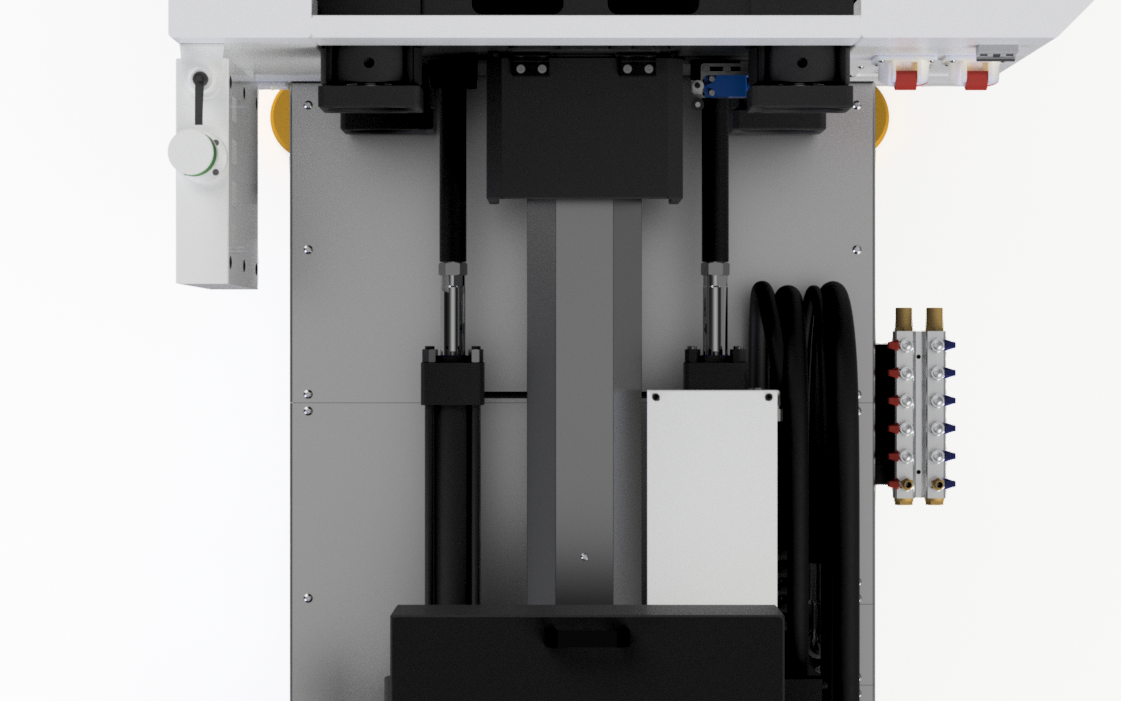

Progressive Lubrication

The Lubrication points on the XENON are closed loop and will give alarm if any of the Lubrication point is blocked. XENON also offer Grease Lubrication which is better than Oil lubrication.

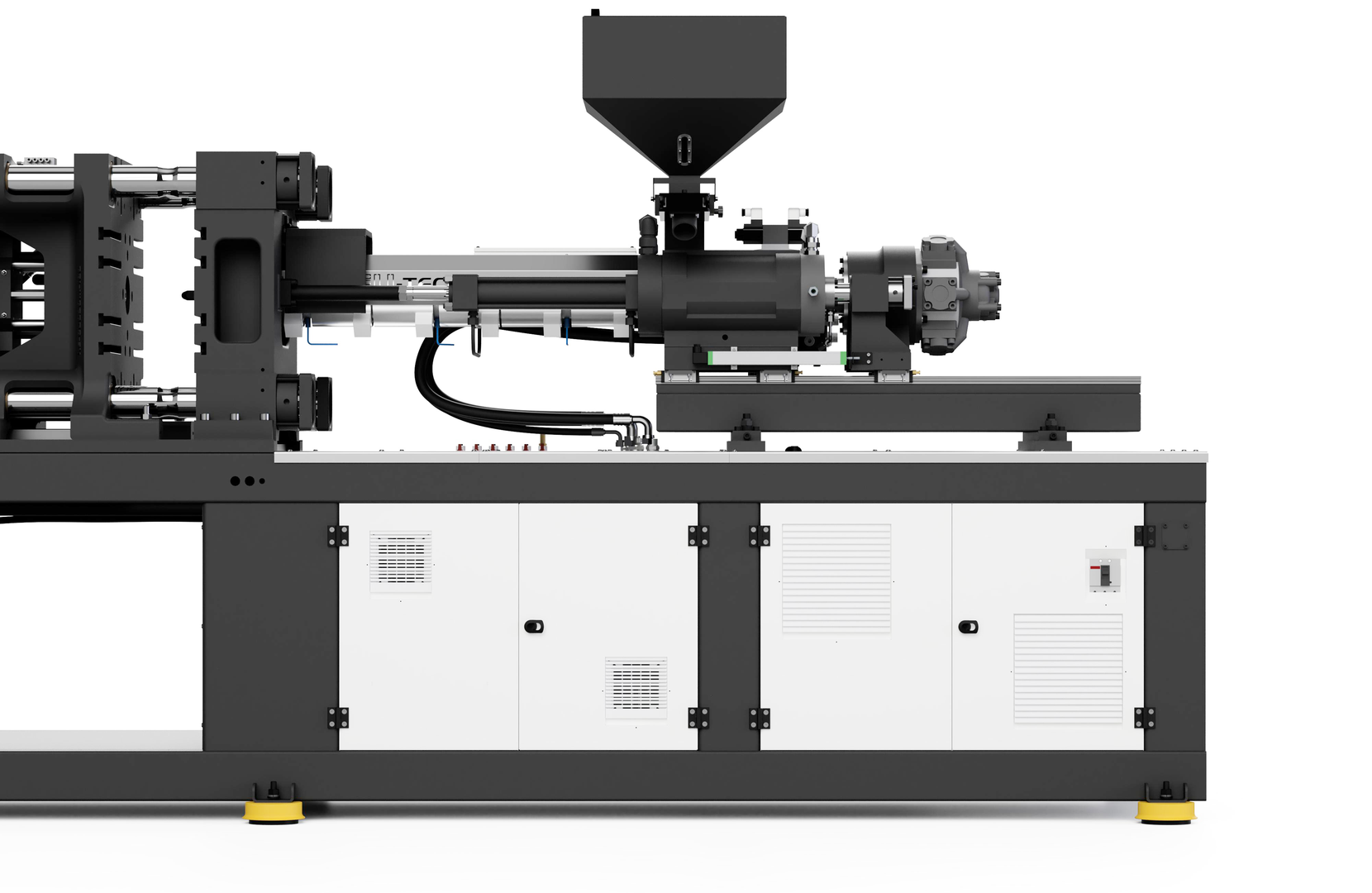

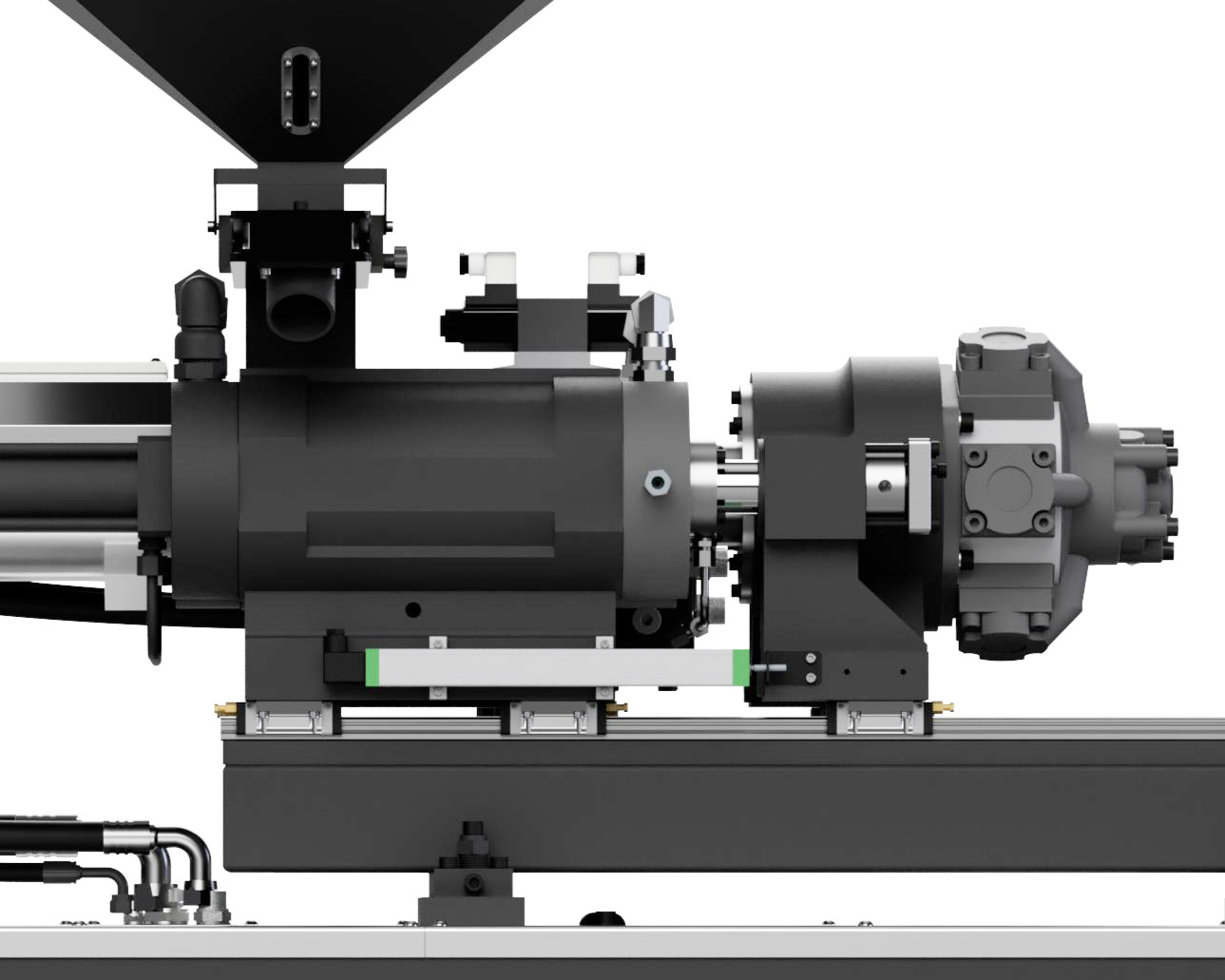

Injection Unit

- High screw RPM offers low refilling time means low cycle time

- Enhanced efficient Screw Design saves Charging time and Electricity

- High Precision Linear Guide rails for less frictional drag

- Larger screw size and stroke with longer L/D Ratio for High production output

- Enhanced design for more accurate proportional back pressure control

- Nozzle Contact force by pressure switch offer precise force

- High quality hydraulic motor ensures consistent refilling in every shot

Dual Carriage Cylinders

Balanced Injection Loads as Nozzle contact force is applied by Dual Carriage Cylinders with pressure switch signal which ensure accurate and precise nozzle contact force in each cycle.

Fast Charging and Injection

The XENON offers Injection speeds of upto 120mm/sec saving a good cycle time which increases the overall efficiency of the machine. The Screw RPMs are more than 200 which ensures high plasticising rate.

Enhanced Screw Design

The newly designed optimised screw is very sucessfull in delivering a homogenous mixture with less energy input. Means this screw is now able to plasticise more material with less electrical consumption in less time.

Proportional Back Pressure

XENON comes with new hydraulic circuit which offers accurate and precise control of back pressure during charging. The accuracy of set back pressure value is now increased and more stable.

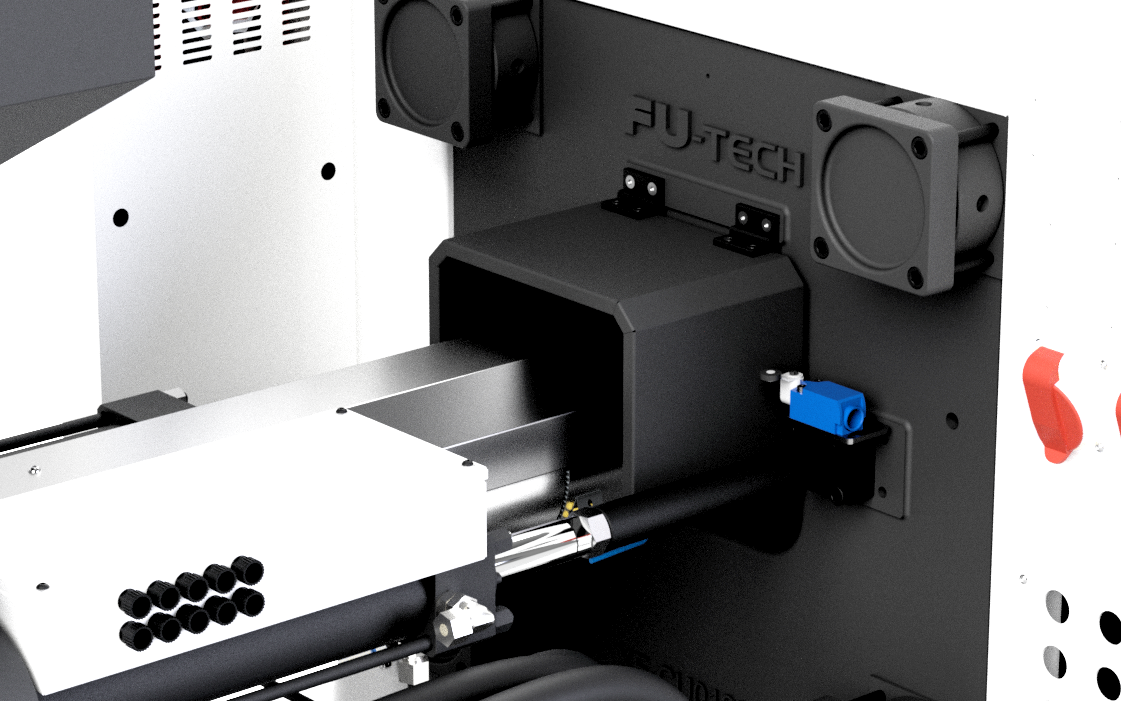

Injection safety purge guard

The safety guard provides extra safety during barrel purging and cleaning. The upturning design makes switching between maintainence and production easier.

Injection Unit with Linear Guide Rails

The friction-less linear guide rails provides precise, high speed and accurate injection. Also stainless steel covers below injection unit increase over all machine cleanliness.